How to Install a Bathroom Sink Stopper

The bathroom sink stopper, a seemingly simple component, plays a crucial role in the functionality and usability of any lavatory. A properly installed stopper allows for water retention within the basin, facilitating tasks such as shaving, hand washing, or soaking items. Conversely, a malfunctioning or improperly installed stopper can lead to water leakage, frustration, and potentially, wasted water and increased utility bills. The installation process, while generally straightforward, requires a methodical approach and an understanding of the various stopper types and their corresponding mechanisms. This article provides a comprehensive guide to successfully installing a bathroom sink stopper, ensuring proper drainage and preventing unwanted leaks.

Before commencing the installation, it is essential to identify the existing stopper type and its operating mechanism. Common types include the lift-rod stopper, the pop-up stopper, the push-and-seal stopper, and the flip-it stopper. Each type utilizes a distinct method to control the opening and closing of the drain. The lift-rod stopper, typically found in older sinks, employs a rod connected to a clevis and spring clip mechanism located behind the drain pipe. The pop-up stopper, a more contemporary design, utilizes a pivoting rod that actuates a stopper disc within the drain. The push-and-seal stopper, also known as a touch-toe stopper, operates by pressing down on the stopper itself to seal and release the drain. The flip-it stopper, a tool-free option, is designed for ease of use and simplicity in installation.

Understanding the nuances of each type is crucial for selecting the appropriate replacement stopper and ensuring compatibility with the existing sink and drain assembly. Furthermore, familiarity with the tools required and the steps involved in disassembly and reassembly is paramount. Failure to properly identify the stopper type or to follow the correct installation procedure can result in leaks or damage to the sink and drain components.

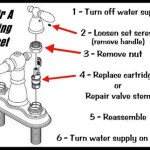

Prior to beginning any plumbing work, safety precautions are paramount. It is recommended to wear safety glasses to protect against debris and gloves to maintain hygiene and protect hands. Turning off the water supply to the sink is an absolute necessity to prevent flooding during the installation process. Typically, shut-off valves are located beneath the sink, one for hot water and one for cold water. Turn both valves clockwise until fully closed. To ensure the water supply is completely shut off, turn on the faucet briefly to relieve any residual pressure in the lines. Keep a bucket and towels handy to catch any remaining water that may be present in the drainpipe or existing stopper assembly.

Gather the necessary tools for the installation. These commonly include: an adjustable wrench, a basin wrench (for loosening tight nuts in confined spaces), pliers, a screwdriver (both flathead and Phillips head), plumber's putty, Teflon tape, and a small container to hold removed parts. It's also wise to have a flashlight to improve visibility underneath the sink.

Key Point 1: Removing the Old Stopper Assembly

The first step in the installation process involves removing the old stopper assembly. The removal procedure varies depending on the type of stopper installed. For a lift-rod stopper, disconnect the lift rod from the clevis located behind the drainpipe. The clevis is typically held in place by a spring clip or a screw. Once the lift rod is disconnected, loosen the nut securing the pivot rod to the drainpipe. The pivot rod connects directly to the stopper. Remove the pivot rod completely, which will allow the stopper to be lifted out of the drain opening. For a pop-up stopper, follow a similar procedure, disconnecting the horizontal rod from the vertical lift rod mechanism. The stopper can then be lifted out. For a push-and-seal stopper, simply unscrew or pull out the stopper from the drain opening. Flip-it stoppers are generally installed without tools and can be removed by simply lifting it out.

After removing the stopper itself, the drain flange, which is the portion of the drain assembly that sits flush against the sink basin, must be detached. This flange is typically secured by a large nut located underneath the sink. Place a bucket under the drain to catch any remaining water. Using a basin wrench or adjustable wrench, carefully loosen the nut. In older sinks, the nut may be corroded and difficult to loosen. Penetrating oil can be applied to help loosen the nut. Once the nut is loosened, carefully remove it and the drain flange from the sink. Inspect the old drain flange and stopper for signs of wear, corrosion, or damage. This information can be useful in determining the cause of any previous leaks or drainage issues.

Thoroughly clean the sink basin around the drain opening. Remove any old plumber's putty or sealant. A putty knife or scraper can be used to remove stubborn residue. Ensure the surface is clean and dry before proceeding with the installation of the new stopper assembly. A clean surface will facilitate a proper seal and prevent future leaks.

Key Point 2: Installing the New Drain Flange and Stopper Mechanism

The installation of the new drain flange and stopper mechanism requires careful attention to detail to ensure a watertight seal. Begin by applying a generous rope of plumber's putty around the underside of the new drain flange rim. The putty should completely encircle the drain opening, ensuring that it will create a seal between the flange and the sink basin. Press the drain flange firmly into the drain opening, centering it carefully. Excess putty will squeeze out from under the flange. This excess putty should be removed with a putty knife or finger, creating a neat and clean appearance.

From underneath the sink, slide the rubber washer, followed by the cardboard or fiber washer, and then the metal washer onto the tailpiece of the drain flange. Secure the assembly with the large nut that was removed from the old drain flange (or the new nut provided with the new drain assembly). Tighten the nut by hand until it is snug. Then, use a basin wrench or adjustable wrench to tighten the nut further, ensuring a secure connection. Do not overtighten, as this can crack the sink basin or damage the drain flange. The goal is to compress the plumber's putty and create a watertight seal.

The next step involves installing the stopper mechanism. For lift-rod and pop-up stoppers, insert the stopper into the drain opening. Position the stopper so that the opening for the pivot rod aligns with the corresponding hole in the drainpipe. Insert the pivot rod through the hole in the drainpipe and into the opening in the stopper. Secure the pivot rod with the nut, tightening it snugly but not overtightening. Connect the lift rod to the clevis. Adjust the height of the lift rod to achieve the desired stopper position. For push-and-seal stoppers, follow the manufacturer's instructions for installation. Typically, this involves screwing the stopper into the drain flange. Flip-it stoppers usually just need to be placed in the drain opening.

Before proceeding, it is imperative to visually inspect the entire assembly for proper alignment and secure connections. Ensure that all nuts and screws are tightened appropriately and that the stopper mechanism operates smoothly. A slight adjustment may be necessary to achieve optimal performance.

Key Point 3: Testing for Leaks and Final Adjustments

After installing the new stopper assembly, testing for leaks is crucial to ensure a successful installation. Turn on the water supply to the sink, both hot and cold. Allow the water to run for a few minutes while observing the drain connections for any signs of leakage. Pay particular attention to the area around the drain flange and the tailpiece connections. If leaks are detected, immediately turn off the water supply and tighten the corresponding connections. In some cases, it may be necessary to disassemble the connection, reapply plumber's putty or Teflon tape, and reassemble the connection.

Once the drain connections are confirmed to be leak-free, test the functionality of the stopper. Close the stopper and fill the sink with water. Observe the water level for any signs of drainage. If the water level drops, the stopper is not sealing properly. Adjust the position of the stopper or the lift rod mechanism to achieve a tighter seal. For lift-rod and pop-up stoppers, the adjustment is typically made by repositioning the clevis or tightening the nut on the pivot rod. For push-and-seal stoppers, the stopper may need to be tightened or adjusted according to the manufacturer's instructions.

After making any necessary adjustments, repeat the leak test to ensure that the stopper is now sealing properly and that there are no leaks in the drain connections. If persistent leaks are encountered, it may be necessary to replace the drain flange or stopper assembly with a new unit. Inspect the drainpipe for any cracks or damage that may be contributing to the leaks. If the drainpipe is damaged, it should be replaced by a qualified plumber.

Finally, clean up the work area and dispose of any waste materials properly. Ensure that all tools are accounted for and stored safely. A properly installed bathroom sink stopper will provide years of reliable service, preventing water waste and enhancing the functionality of the lavatory.

Regular maintenance of the sink stopper can help to prevent clogs and ensure optimal performance. Periodically remove the stopper and clean away any hair, soap scum, or other debris that may have accumulated. A small brush or tweezers can be used to remove stubborn debris. Flushing the drain with hot water can also help to prevent clogs. By following these simple maintenance tips, one can extend the life of the sink stopper and prevent costly plumbing repairs.

Install A Drain Stopper So The Is Removable

How To Replace A Sink Stopper Quick And Simple Home Repair

Quick Tip 26 Pop Up Stopper Sticks Misterfix It Com

Getting Spring Clip To Stay On

Step By Guide On How To Install Sink Pop Up Drain Stopper

How To Install Bathroom Sink Drain Queen Bee Of Honey Dos

Fixing Tricky Pop Up Drain Sink Stopper Mechanisms Efficient Plumber

Installing This Anti Clogging Pop Up Drain Stopper Will Save You Thousands Bathroom How To Diy

How To Fix A Bathtub Or Sink Pop Up Stopper

How To Install Bathroom Sink Drain Queen Bee Of Honey Dos

See Also