Bathroom Sink Pop Up Drain Assembly: A Comprehensive Guide

The bathroom sink pop-up drain assembly is a seemingly simple yet crucial component of any bathroom plumbing system. Its primary function is to control the flow of water in and out of the sink basin, allowing for filling and draining as needed. This mechanism, while ubiquitous, involves a specific set of parts and installation requirements that are essential for proper functionality and prevention of leaks and other plumbing issues. This article provides a detailed overview of the various aspects of a bathroom sink pop-up drain assembly, covering its components, installation process, troubleshooting common problems, and maintenance tips.

Understanding the Components of a Pop-Up Drain Assembly

A standard pop-up drain assembly comprises several interconnected parts, each contributing to the overall operation. A thorough understanding of these components is necessary for effective installation, repair, and maintenance.

The first major part is the

drain body

. This is the main housing of the assembly, typically made of brass, PVC, or other durable materials. It features a threaded section on the bottom that connects to the tailpiece and subsequently to the P-trap. The drain body also houses the stopper mechanism and features an opening for the pivot rod.The

stopper

, also known as the drain plug, is the component that physically blocks the drain opening. Stoppers can be made from various materials, including plastic, rubber, and metal. It’s design impacts how easily and effectively it seals the drain opening.The

pivot rod

is a horizontal metal bar that connects to the lift rod, which is located near the faucet. When the lift rod is raised or lowered, the pivot rod rotates, raising or lowering the stopper to open or close the drain.The

lift rod

, also known as the pop-up rod or knob, is the vertical rod located near the faucet that is used to operate the drain. It connects to the pivot rod via a clevis or strap.The

clevis or strap

is a small metal piece that connects the lift rod to the pivot rod. It typically has multiple holes to adjust the height of the stopper.The

tailpiece

is a pipe that connects to the bottom of the drain body and extends down to the P-trap. It is usually made of PVC or brass and is secured to the drain body with a slip nut and washer.The

flange

is the visible part of the drain assembly that sits inside the sink basin. It provides a finished look and helps to create a watertight seal. It’s typically made of metal, such as brass, chrome, or stainless steel.Finally,

washers and nuts

are essential for creating watertight seals between the various components. These are typically made of rubber or plastic and are placed strategically to prevent leaks. The most common types are the flange washer (placed between the flange and the sink basin) and the slip nut washers (used to seal the connections between the drain body, tailpiece, and P-trap).Installing a Bathroom Sink Pop-Up Drain Assembly

Proper installation of the pop-up drain assembly is crucial for preventing leaks and ensuring smooth operation. While it may seem straightforward, careful attention to detail is necessary. Begin by gathering all necessary tools, including a basin wrench, adjustable wrench, plumber's putty or silicone sealant, and a clean cloth.

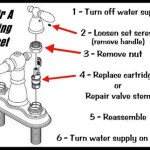

The first step is to

remove the old drain assembly

. This involves disconnecting the tailpiece from the P-trap and then unscrewing the retaining nut that holds the drain body to the sink. Be prepared for some residual water to drain out during this process.Next,

clean the sink opening thoroughly

. Remove any old plumber's putty or sealant, ensuring a clean surface for the new flange. Use a solvent if necessary to remove stubborn residue.Apply a rope of

plumber's putty or silicone sealant

to the underside of the new drain flange. Ensure a consistent and generous application to create a watertight seal between the flange and the sink basin. Some prefer silicone sealant for longevity but plumber's putty is generally easier to work with.Insert the drain flange into the sink opening, pressing it firmly into the plumber's putty or sealant. From underneath the sink, slide the rubber washer and then the cardboard or plastic friction washer onto the drain body. Then, screw on the mounting nut by hand, tightening it until snug.

Use a basin wrench to

tighten the mounting nut

further, ensuring a secure and watertight seal. Avoid overtightening, which could crack the sink or damage the drain body. Periodically check the flange from above to ensure it remains centered and flush with the sink basin.Install the

pivot rod and stopper

. Insert the stopper into the drain body from above, aligning the stopper with the opening for the pivot rod. Insert the pivot rod through the opening in the drain body and connect it to the stopper. Secure the pivot rod with the pivot rod nut, tightening it just enough to allow the stopper to move freely without leaking.Attach the

lift rod to the pivot rod

using the clevis or strap. Adjust the height of the stopper by repositioning the clevis on the lift rod. The stopper should seal the drain completely when the lift rod is in the down position and open fully when the lift rod is raised.Finally, connect the

tailpiece to the drain body

using a slip nut and washer. Ensure the washer is properly seated before tightening the slip nut. Then, reconnect the tailpiece to the P-trap, again using slip nuts and washers. Tighten all connections securely, but avoid overtightening. Turn on the water and check for leaks at all connections. If leaks are present, tighten the connections further or disassemble and reapplied sealant/plumber's putty as necessary.Troubleshooting Common Issues with Pop-Up Drain Assemblies

Despite careful installation, various issues can arise with pop-up drain assemblies. Recognizing these problems and understanding how to address them is crucial for maintaining a functional bathroom sink.

One common problem is a

leaky drain

. Leaks can occur at various points, including the flange, the pivot rod nut, the tailpiece connection, or the P-trap connection. To identify the source of the leak, dry off all the connections and then run water in the sink. Observe carefully to see where the water is originating.If the leak is at the

flange

, the most likely cause is a faulty seal between the flange and the sink basin. This may require removing the flange, cleaning the surfaces, and reapplying plumber's putty or silicone sealant. Ensure a generous and consistent application to create a watertight seal.A leak at the

pivot rod nut

typically indicates that the nut is not tight enough or that the O-ring inside the nut is damaged. Try tightening the nut slightly. If the leak persists, remove the nut and inspect the O-ring. Replace the O-ring if it is cracked, worn, or damaged. A dab of silicone grease on the O-ring during reassembly can also help to improve the seal.Leaks at the

tailpiece or P-trap connections

are usually caused by loose slip nuts or damaged washers. Tighten the slip nuts, ensuring they are snug but not overtightened. If the leak continues, disassemble the connection and inspect the washer. Replace the washer if it is cracked, deformed, or missing. Ensure that the washer is properly seated before reassembling the connection.Another frequent issue is a

stuck or sluggish stopper

. This can be caused by a buildup of hair, soap scum, and other debris in the drain body or around the stopper. To address this, remove the stopper and clean it thoroughly. Use a small brush or a bent wire to remove any debris from the drain body. Flush the drain with hot water to help dislodge any remaining buildup. If the problem persists, the P-trap may need to be cleaned as well.Occasionally, the

lift rod may become disconnected

from the pivot rod. This can be caused by a loose clevis or a broken connection. Inspect the clevis and ensure that it is securely attached to both the lift rod and the pivot rod. If the clevis is broken, replace it. Also, ensure that the pivot rod is properly seated in its opening and that the pivot rod nut is secure.Finally, the

stopper may not seal properly

, allowing water to slowly drain from the sink. This can be caused by a misaligned stopper or a worn stopper seal. Adjust the height of the stopper by repositioning the clevis on the lift rod. Ensure that the stopper is centered in the drain opening and that it makes full contact with the drain seat. If the stopper seal is worn or damaged, the entire stopper assembly may need replacement.

Luxury Bathroom Sink Pop Up Drain With Extended Thread

Pop Up Lift Turn Pull Out Stopper Bathroom Sink Drains

Gerber Part G0043973 Bathroom Sink Metal Pop Up Drain Assembly In Chrome Drains Parts Home Pro

Pop Up Drain Rod Assembly With Overflow Bathroom Sink Are Sheng

Yasinu B007a Bathroom Pop Up Drain Assembly Vessel Sink Stopper With Overflow Chrome Ynb007a02ch The Home

Rp34953ss Drain Assembly Bathroom Plastic Pop Up

Pop Up Lift Turn Pull Out Stopper Bathroom Sink Drains

Rless Bathroom Sink Pop Up Drain Assembly Chrome Com

Vigo Vessel Bathroom Sink Pop Up Drain And Mounting Ring

Kraus Brushed Gold Bathroom Decorative Sink Drain In The Drains Stoppers Department At Com

See Also