DIY Floating Shelves For Bathroom: A Comprehensive Guide

Floating shelves offer a stylish and practical storage solution for bathrooms, maximizing space while maintaining a clean, minimalist aesthetic. This article provides a comprehensive guide to constructing and installing DIY floating shelves specifically tailored for bathroom environments. It covers material selection, design considerations, construction steps, and installation techniques, ensuring a successful and durable outcome. Considerations for moisture resistance and load-bearing capacity are also addressed.

Material Selection: Prioritizing Durability and Moisture Resistance

Choosing the right materials is crucial for the longevity and functionality of bathroom floating shelves. The bathroom environment is characterized by high humidity and fluctuating temperatures, making moisture resistance a primary concern. Furthermore, the material should be robust enough to support the intended weight of toiletries, towels, and decorative items.

Solid wood, while aesthetically appealing, can be susceptible to warping, cracking, and mold growth in humid conditions. If solid wood is preferred, select hardwoods like teak, cedar, or mahogany, known for their natural resistance to moisture. These woods are more expensive and require proper sealing and finishing to enhance their protective qualities.

Engineered wood products, such as plywood and MDF (Medium Density Fiberboard), are often a more cost-effective alternative. Plywood, consisting of multiple layers of wood veneer glued together, offers good strength and stability. Marine-grade plywood is particularly suitable for bathrooms due to its superior water resistance. MDF, a composite material made from wood fibers, is smooth and easy to paint, but it is highly absorbent and requires thorough sealing to prevent swelling and disintegration. Moisture-resistant MDF options are available and should be prioritized.

For shelving hardware, stainless steel or galvanized steel brackets are recommended to prevent rust and corrosion. These materials are specifically designed to withstand moisture and are available in a variety of sizes and configurations to suit different shelf dimensions and load requirements. Avoid using untreated steel or iron, as these will quickly corrode in the humid bathroom environment.

The selection of finishes is equally important. Opt for waterproof or water-resistant paints, stains, and sealants. Oil-based paints and varnishes provide a durable, water-repellent coating. Polyurethane finishes are also a good choice, as they offer excellent protection against moisture and scratches. Ensure all surfaces, including edges and undersides, are adequately sealed to prevent water penetration.

Design and Construction: Balancing Aesthetics and Functionality

Before commencing construction, carefully consider the design and dimensions of the floating shelves. The size and number of shelves should be proportionate to the bathroom space and tailored to the specific storage needs. Measure the available wall space accurately and sketch out a detailed plan, noting the desired shelf length, depth, and spacing.

Shelf depth is an important consideration. Deeper shelves provide more storage space but can visually overwhelm a small bathroom. A typical shelf depth ranges from 6 to 12 inches. The length of the shelf will depend on the available wall space and the intended use. Longer shelves may require additional support to prevent sagging.

The construction process involves several key steps. First, cut the shelf material to the desired dimensions using a saw. Ensure the edges are straight and smooth. Sand all surfaces thoroughly to remove any rough spots and prepare the wood for finishing.

If using plywood or MDF, consider adding edge banding to the exposed edges. Edge banding is a thin strip of wood veneer or plastic that is glued to the edges of the shelf, providing a finished look and protecting the core material from moisture. Apply edge banding with a heat-activated adhesive and trim any excess material with a utility knife.

Apply the chosen finish to the shelf, following the manufacturer's instructions. Apply multiple coats, allowing each coat to dry completely before applying the next. Sand lightly between coats to create a smooth, even surface. Pay particular attention to sealing the edges and undersides of the shelf, as these areas are most vulnerable to moisture damage.

There are various methods for creating the floating effect. One common approach involves using hidden shelf brackets. These brackets consist of a steel rod or plate that is mounted to the wall and inserts into a corresponding hole or slot in the shelf. The shelf is then slid onto the bracket, concealing the support structure.

Another method involves creating a hollow-core shelf. This type of shelf consists of a frame made from wood or metal, with thin panels attached to the top and bottom. The frame provides structural support, while the hollow core reduces the overall weight of the shelf. Hidden brackets can be attached to the frame, allowing the shelf to be mounted to the wall.

Installation: Ensuring Stability and Load-Bearing Capacity

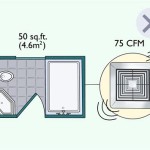

Proper installation is essential for the safety and stability of floating shelves. Before installation, locate the wall studs using a stud finder. Wall studs are vertical framing members that provide structural support for the wall. Attaching the shelf brackets directly to the wall studs will ensure maximum load-bearing capacity.

If wall studs are not available in the desired location or if the shelf is significantly longer than the distance between studs, consider using drywall anchors. Drywall anchors are designed to provide secure attachment points in drywall. Choose heavy-duty drywall anchors that are capable of supporting the weight of the shelf and its contents. Follow the manufacturer's instructions for installing the drywall anchors.

Use a level to ensure the shelf brackets are mounted horizontally. Mark the location of the bracket mounting holes on the wall and drill pilot holes. Attach the brackets to the wall using screws. If attaching to wall studs, use wood screws that are long enough to penetrate the stud by at least 1.5 inches. If using drywall anchors, use screws that are specifically designed for use with the chosen anchors.

Once the brackets are securely mounted to the wall, slide the shelf onto the brackets. If using hidden shelf brackets with steel rods, ensure the rods are fully inserted into the corresponding holes in the shelf. Use a rubber mallet to gently tap the shelf into place, if necessary.

To further secure the shelf, consider using construction adhesive. Apply a small amount of construction adhesive to the top of the brackets before sliding the shelf into place. The adhesive will help to prevent the shelf from slipping or moving. Ensure the adhesive is compatible with the shelf material and the wall surface.

After installation, test the stability of the shelf by applying gentle pressure to different areas. If the shelf feels wobbly or unstable, reinforce the attachment points by adding additional screws or using larger drywall anchors. Avoid overloading the shelf with excessive weight, as this can compromise its stability and lead to sagging or failure.

For tiled bathroom walls, use a specialized drill bit designed for drilling through tile. Apply masking tape to the tile surface before drilling to prevent chipping or cracking. Drill slowly and carefully, applying light pressure. Once you have drilled through the tile, switch to a regular drill bit to drill into the wall behind the tile. Use tile anchors designed for this purpose to ensure a secure hold.

Regular maintenance is crucial for extending the lifespan of bathroom floating shelves. Wipe down the shelves regularly with a damp cloth to remove dust and grime. Avoid using harsh cleaning chemicals, as these can damage the finish. Inspect the shelves periodically for any signs of water damage or corrosion. Address any issues promptly to prevent further deterioration.

By carefully selecting materials, designing thoughtfully, and installing diligently, constructing DIY floating shelves for a bathroom can be a rewarding project that enhances both the functionality and aesthetics of the space. Prioritizing moisture resistance and load-bearing capacity ensures a durable and safe storage solution for years to come. The flexibility of DIY allows for customization to perfectly match the existing décor and specific storage needs of any bathroom.

25 Creative Diy Bathroom Shelf Ideas The Handyman S Daughter

Diy Floating Shelves Above Toilet Liz Pacini

Diy Floating Bathroom Shelves Stacy Risenmay

Simple Diy Floating Shelves In The Bathroom Simply Organized

Easy Diy Floating Shelves Shelf Tutorial Free Plans

Diy Rustic Wood Metal Bathroom Shelves Liz Marie Blog

Diy Floating Shelves In Linen Closet Casa Watkins Living

Diy Floating Shelves In Bathroom

Let S Build Some Quick Floating Shelves Thrifty Decor Diy And Organizing

How To Make Easy Diy Floating Shelves Field Court

See Also